Over the past few months, I have made reference to developing work for this exhibition.

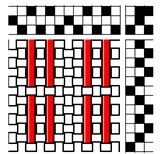

Over 20 years ago woven shibori was launched onto the world stage by Catharine Ellis of North Carolina, USA and Kay Faulkner of Birkdale, Australia. Their research occurred independently and simultaneously. (RAG publicity)

This exhibition celebrates that significant milestone.

Redland Art Gallery, Cleveland Australia

10th March – 14th April 2019

Before I even write about the exhibition, I would like to acknowledge the support given by the gallery and staff in hosting this exhibition. They did the hanging. They have done a superb job. As you look at images take note of how they are presented. Having the work off the wall shows it to the best advantage and allows those weavers who want to see the back to be able to do so.

The Opening on Friday 8th March was extremely well attended. Janet de Boer OAM did the honours and provided a very engaging experience.

This photo of Catharine and myself is courtesy of Redland Art Gallery with the photography by John Muller

Here are views of the gallery from the left and working around the gallery.

Both Catharine and I had a series of work in the City Council’s foyer, just outside the gallery.

Some of the crowd at the opening.

I enjoyed the interaction of visitors with the “ladies” from my installation of “Give them voice.” This is images is from the Artist talks held on the following Sunday.

The following is my artist statement in italics with images of my work interspersed throughout.

The year was 1998. I was heading to Convergence, the biggest conference for hand weavers in the world. Before I left I had been informed that my article on Loom Controlled Shibori had been accepted for the prestigious weaving magazine, Weavers. En route, I was delighted to hear that my work was also to appear on the cover. What an honour! Convergence was also where I’d heard a weaver would be teaching “Woven Shibori Resist”. Can you imagine, this was going to be the meeting of two individuals who had developed this technique independently though at the same time on opposite sides of the world? We met. We discussed our different approaches, we discovered many personal parallels. We became friends.

“From the archives”: the article and table runners, 1998.

“Landscape” 1997 from my first exhibition featuring woven shibori, hand woven and dyed wool, acid dyes

Over twenty years ago when I first started working with the technique of loom controlled shibori which soon morphed into being known as simply woven shibori woven shibori, it was simply a means of adding a dye pattern to cloth. I was fascinated by how many different dye patterns could be achieved. My early work was very heavily influenced by traditional shibori approaches. Then I became interested in using different media in combination with dye or even instead of dye. It was all about adding pattern to a cloth. You wove, you pulled up the threads, added some dye or applied a treatment and then on undoing the resist, a pattern was exposed. The experience of revealing the pattern was addictive. It was the cloth.

Detail of “Inspired by tradition” 2010, hand woven lace with woven shibori, silk, acid dyes. Photo Don Hildred.

Detail of “Controlled Simplicity” 2010, hand woven fabric with complimentary woven shibori, silk, acid dyes, three panels hand sewn together.

After a while, I wanted to take more control of the process. While there was still an element of serendipity in the dyeing, I became more fascinated by the relationship between fabric structure and the dye process. No longer was an overall dye pattern important. The starting point was very much structure and its potential from both perspectives. I made the structure work. I was inspired by structure.

Detail of untitled kimono, 2010, Hand woven silk, shadow weave, double ikat, warp and weft shibori, acid dyes.

Detail of untitled kimono, 2010, Hand woven silk with cotton/linen, twill fabric, weft shibori woven on a draw loom, acid dyes.

Over time, the technique of woven shibori became a familiar tool and is now just one of the many that I use in my studio practice. In developing my work, I do not start with dye pattern or with structure but rather from the story that I want to tell.

This exhibition has allowed me to present both work from a time span of over twenty years and current work. It has given me an opportunity to reflect on how my use of the technique has changed and of the role it has played of my studio practice.

Current work: Reflecting on where I live.

I am a long time resident of this area. In fact I have lived here for nearly 40 years. It is the place where my husband and I settled to when we got married. It’s where our children were born, raised and left from and have even come home to. It’s where he died. It’s where I live and create. It does in some way give me a sense of belonging.

I have a general awareness of the history of this area of The Redlands. I have long been aware of the historic homes: Ormiston House, Whepstead Manor, The Pines, The Old Court House and the like. There are roads named after early settlers. Perhaps its history could well provide a starting point for inspiration for a new body of work. And so I began researching. I found out lots about the men who settled here. How much reference was made to females? Not much of course and the further back in time, the less you find. Sometimes even in the family notices, it is difficult to see the real women.

For the purposes of developing one theme for this exhibition, I decided to limit research to the female history before 1900’s. That will allow for a time frame of about 50 years when this area first had white settlement. As an aside, while I certainly acknowledge the first people of this land, I don’t feel qualified to present it and nor is it the focus of this research. I have had a very interesting time visiting the Local History section in the library, going on line for oral history and old newspapers, visiting the Museum, having discussion with people who have stories to tell. Everyone who I’ve had connection with in this project have been extremely helpful. I certainly appreciate their help. I have collected stories and references and found out all manner of interesting things. And sometimes there’s an echo of my family history even though I my family heritage is not from here.

The story cloths presented in the series Give them Voice are of 8 women representative of their time. Their stories are of real women though their names have been withheld so that they can become representatives of their contemporaries. Their figures are partially here as only part of their story can be found. However they were a part in the early history of this city and have left their mark, reflective of the way that the shibori has marked this fabric.

Visitors to the gallery, take time to read their stories. In much the same way that it took me some effort to read they also have to take time to follow the diagonal weaving line so that the stories can be read. They have the opportunity to wander amongst this community of ladies and have a conversation.

Close up detail of “Give them voice”.

Close up detail of one of the 8 panels: “My family sent me”, 2018, hand woven story cloth, cotton, triacetate/acrylic, natural dyes (eucalyptus and my grandmother’s pomegranate).

Please go to this like for more details of “Give them voice”

“Family Notices 1866”. 2019, Hand woven, cotton with linen, woven shibori, natural dyes (mud: red dirt from Wellington Point), printed family notice with selected entries from the newspaper: The Queenslander, 3rd March 1866, embroidery.

The process of making these women “real” required following the stories that would appear and disappear. I followed their trails and I have gained awareness. The series Tracks and trails reflects on the ephemeral nature of their impact on the land, of a moment passing in time and a story that is partly uncovered.

“Tracks and Trails I”, 2019, hand woven, double weave, wool layer and triacetate acrylic layer, woven shibori, acid dyes.

Tracks and Trails II”, 2019, hand woven, double weave, cotton, linen, woven shibori, natural dyes (pomegranate and iron).

Tracks and Trails III” 2019, hand woven, double weave, cotton, woven shibori, natural dyes (pomegranate and iron), textile paint. Tyre courtesy of Nic McCarthy.

Tracks and Trails IV, 2019, hand woven, double weave, cotton, wool, woven shibori, fibre reactive and acid dyes.

Researching work for Give them voice, also encouraged me to reflect on progress. Progress has brought huge advances in the status of women, medicine, the way that we live and the things that make life easier. However it also brings with it stresses on the land and the environment. It brings more development, more roads, and more people. Often when we look at where progress is taking us we wish that it can be halted.

Progress I, 2019, hand woven, cotton with linen, woven shibori, dyed with eucalyptus (Tallowwood), dyed with rusty bits including iron from Ormiston, fabric paint, credit Andrew Faulkner for access to his tyres.

Progress II, 2018, hand woven, cotton, painted warp, triacetate acrylic supplementary weft design based on the word “progress” which has been distorted, woven shibori, fibre reactive dyes.

This new work allows me to reflect on the impermanence of our era’s mark on the land no matter what our gender or race. Will our mark or our story be easily read in the future? Will future generations be able to find research on the people living now? What will they think of these times that we live in?

It is exciting and I am honoured that I have been asked to tour this work to other galleries. Those will be announced later.

Posted by kayfaulkner

Posted by kayfaulkner